Industry Welded Cylinder

Chlorine Gas Cylinder,Chlorine Tank

150lb Chlorine Cylinder

- Standard: DOT 3AA

- Max filling Capacity: 70kg / 150lb

- Water Capacity: 54 L

- Working Pressure: 150bar (2175psi)

- Test pressure: 250bar (3625psi)

- Material: 37Mn

- Thead Valve Standard: CGA /DIN/GB/EN/BS/ANSI

800L Chlorine Cylinder

- Standard: ISO/GB/ASME

- Thickness: 12mm

- Water Capacity: 800L

- Working pressure: 300bar

- Test pressure: 450bar

- Material: HP345

- Thread Valve Standard: CGA /DIN/GB/EN/BS/ANSI

840L Chlorine Cylinder

- Standard: ISO/GB/ASME

- Thickness: 12mm

- Water Capacity: 840L

- Working pressure: 300bar

- Test pressure: 450bar

- Material: HP345

- Thread Valve Standard: CGA /DIN/GB/EN/BS/ANSI

900kg Chlorine Cylinder

- Standard: ISO/GB/ASME

- Max filling Capacity: 900kg

- Water Capacity: 720L

- Working pressure: 300bar

- Test pressure: 250bar (3625psi)

- Material: 37Mn

- Thead Valve Standard: CGA /DIN/GB/EN/BS/ANSI

1 ton chlorine cylinder

- Standard: ISO/GB/ASME

- Max filling Capacity: 1000kg

- Water Capacity: 800L / 840L

- Working Pressure: 150bar (2175psi)

- Test pressure: 250bar (3625psi)

- Material: 37Mn

- Thead Valve Standard: CGA /DIN/GB/EN/BS/ANSI

The liquid chlorine bottles available on the general market have high-pressure seamless, commonly used water from 4L-80L, and welded, commonly used water from 40L-840L, liquid chlorine filling volume (kg) from 5kg to 1000kg.

High pressure seamless chlorine cylinders

Seamless chlorine cylinder(with ISO/ DOT /GB standard)

| Water Capacity | Filling weight | Diameter(mm) | Height(mm) |

|---|---|---|---|

| 37L | 100lbs | 219 | 1350 |

| 55L | 150lbs | 232 | 1450 |

| 56L | 70kg | 232 | 1460 |

Welded Chlorine Cylinders/Tank

Welded chlorine cylinder(with ASME / ISO / GB standard)

| Water Capacity | Filling weight | Diametermm) | Height(mm) |

|---|---|---|---|

| 40L | 50kg | 250 | 1080 |

| 56L | 70kg | 300 | 1000 |

| 100L | 120kg | 350 | 1300 |

| 128L | 160kg | 370 | 1450 |

| 400L | 500kg | 600 | 1800 |

| 800L | 1000kg | 800 | 2000 |

| 840L | 1000kg | 800 | 2200 |

| 1000L | 1250kg | 900 | 2030 |

Minsheng Group is a leading manufacturer of liquid chlorine cylinders, liquid ammonia cylinders, refrigeration gas cylinders and welded cylinders for other industries. Reliable quality, competitive prices, we provide comprehensive testing prior to delivery, together with third party test reports

Minsheng uses high-quality steel plates and perfect welding technology to ensure the long life of liquid chlorine cylinders, liquid ammonia cylinders and other industrial welded gas cylinders.

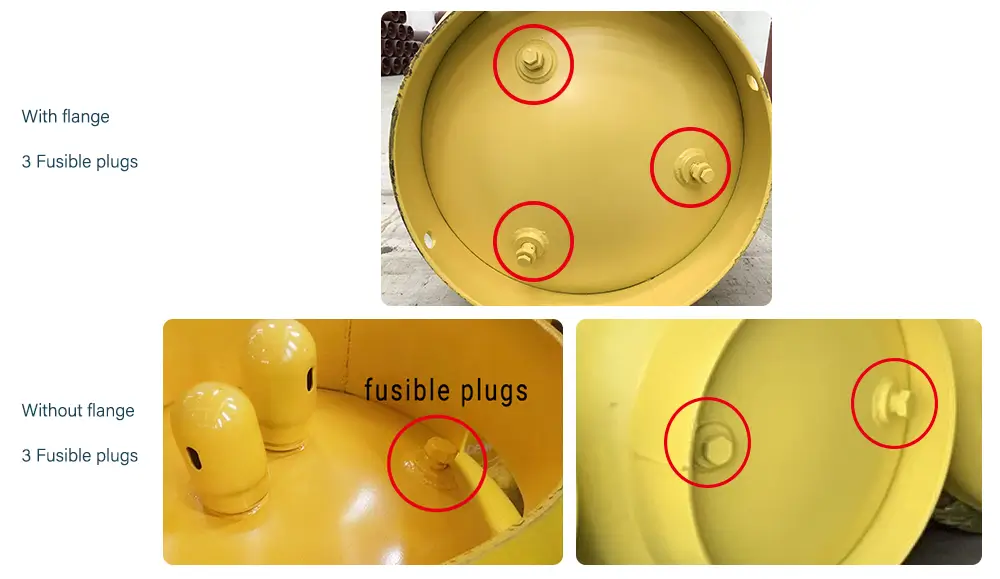

Our chlorine bottles are available in two models: flanged chlorine bottles and flangeless chlorine bottles.

Why do chlorine gas cylinders have fusible plugs?

“Fusible plug” is a safety device installed to ensure the safety of gas cylinders and pressure vessels.

Working principle: The melting temperature of the fusible plug of the liquid chlorine gas cylinder is 65℃. The low melting point alloy melts at a higher temperature to open the channel to allow chlorine to be discharged from the air originally filled in the fusible alloy to release the pressure.

Manufacturing Process of Chlorine Cylinder

Minsheng uses high-quality steel plates and perfect welding technology to ensure the service life of industrial welding gas cylinders such as chlorine cylinders and ammonia cylinders. It strictly produces and tests according to standards to ensure the safety of liquid chlorine cylinders.

Shell Process

Cutting → punching → punching long hole → pre-bending → large protective cover lettering → rolling → welding → pressing

Cylinder Body

Cutting plate → gas cutting bevels on both sides → rust removal at both ends → pre-bending at both ends → rolling → longitudinal seam and test plate welding → campus → non-destructive testing

Head Processing

Cutting plate → Deburring → Calendering → Head beveling → Head drilling → Head polishing

Assembly chlorine gas cylinder

Assembly and welding, non-destructive testing, heat treatment, hydraulic test, gas tightness test